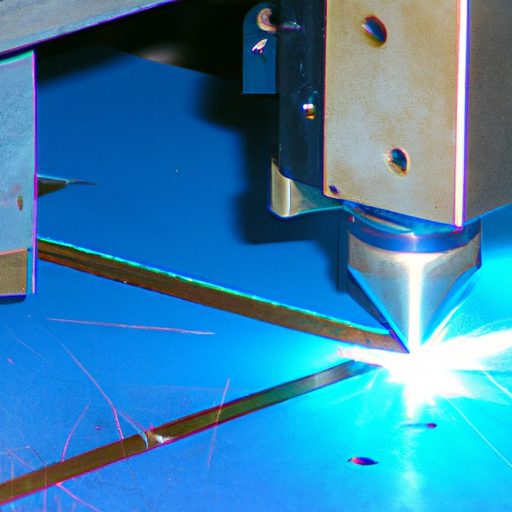

Laser cutting has revolutionized the field of precision cutting, offering unparalleled benefits and advantages over traditional methods. In this article, we explore the numerous advantages of utilizing laser cutting technology in precision cutting applications. From its exceptional cutting accuracy to its ability to work with a wide range of materials, laser cutting has become the go-to choice for industries seeking precise and efficient cutting solutions. Join us as we uncover the remarkable benefits of laser cutting and its impact on the world of precision cutting.

Review contents

Precision Cutting with Laser Technology

Precision cutting is a crucial process in various industries, from manufacturing to fashion design. With advancements in technology, laser cutting has emerged as a highly effective method for achieving accuracy and precision in cutting various materials. In this article, we will explore the benefits of using laser cutting in precision cutting and how it revolutionizes the way we approach cutting tasks.

1. High Precision and Accuracy

1.1. Narrow Kerf Width

One of the significant advantages of laser cutting is its ability to produce narrow kerf widths. The kerf refers to the width of the cut made by the laser beam. With traditional cutting methods, the kerf width tends to be wider, leading to material wastage. Laser cutting, on the other hand, offers a minimal kerf width, allowing for precise cuts and optimal material utilization. This ensures cost-effective production and minimizes material waste, making laser cutting an eco-friendly choice.

1.2. Minimal Heat Affected Zone (HAZ)

Heat is often a concern when it comes to cutting certain materials, as excessive heat can cause damage or distortion. Laser cutting solves this problem by producing a minimal heat affected zone (HAZ). The HAZ refers to the area surrounding the cut where the material may undergo thermal changes due to the heat generated during the cutting process. With laser cutting, the HAZ is significantly reduced, resulting in less thermal stress on the material. This preserves the structural integrity and quality of the cut material, making laser cutting ideal for delicate or heat-sensitive materials.

1.3. Reduced Material Distortion

Traditional cutting methods, such as sawing or mechanical cutting, can often cause material distortion due to the physical force applied during the process. Laser cutting eliminates this issue by precisely focusing the laser beam on the desired cutting path. The concentrated and controlled nature of laser cutting minimizes any material distortion, ensuring a clean and accurate cut every time. This is particularly advantageous for intricate or complex designs that require precise detailing without compromising the material’s integrity.

2. Versatility in Materials

Laser cutting technology offers unparalleled versatility when it comes to cutting different materials. Whether it is metals, plastics, fabrics, or leather, lasers can handle a wide range of materials with ease, making it a go-to solution for various industries.

2.1. Metals

Laser cutting has revolutionized metal cutting processes. Whether it is steel, aluminum, brass, or titanium, lasers can cut through these metals with high precision and accuracy. The ability of lasers to cut complex shapes and intricate patterns on metal surfaces makes them a valuable tool in industries such as automotive, aerospace, and jewelry making. The clean and precise cuts achieved through laser cutting also eliminate the need for additional finishing processes, saving time and resources.

2.2. Plastics

Plastics are commonly used in industries such as packaging, signage, and consumer goods. Laser cutting provides a perfect solution for cutting plastic materials, thanks to its versatility and precision. Whether it’s acrylic, polycarbonate, or PVC, lasers can cut through plastics, producing smooth edges and clean cuts. The ability to cut intricate designs and complex shapes makes laser cutting a preferred choice for industries that require precision and flexibility in plastic fabrication.

2.3. Fabrics and Leather

Laser cutting has revolutionized the textile and fashion industry. From intricate lace patterns to custom embroidery designs, lasers can achieve precise cuts and engraving on fabrics and leather. Traditional cutting methods often pose challenges due to fabric fraying or leather distorting during cutting. Laser cutting eliminates these issues, providing clean cuts without compromising the delicate nature of textiles and leather. This opens up new possibilities in design and customization, allowing designers to unleash their creativity and bring their visions to life.

5.3. Sustainable and Low Energy Consumption

In addition to the precision and versatility it offers, laser cutting is also an environmentally friendly option. Laser cutting machines consume significantly less energy compared to traditional cutting methods. The laser beam itself is highly focused, requiring minimal power to perform the cutting task effectively. This low energy consumption translates into reduced carbon emissions and a smaller environmental footprint.

Furthermore, laser cutting reduces material waste due to its narrow kerf width and precise cuts. Traditional cutting methods often result in larger kerf widths and excessive material wastage. With laser cutting, materials are utilized more efficiently, minimizing waste and promoting sustainable practices.

In conclusion, laser cutting technology revolutionizes precision cutting in various industries. Its ability to achieve high precision and accuracy, minimal heat affected zone, and reduced material distortion make it the go-to choice for intricate and delicate cutting tasks. The versatility of laser cutting across metals, plastics, fabrics, and leather opens up new possibilities in design and fabrication. Additionally, laser cutting is a sustainable option with low energy consumption and minimized material waste. As we continue to embrace technological advancements, laser cutting will undoubtedly play an increasingly vital role in precision cutting, pushing boundaries and transforming industries.