Welding is an essential process in various industries, but it also comes with its fair share of risks. To ensure a safe working environment, it is crucial to take the necessary safety precautions when engaging in welding activities. From proper personal protective equipment to maintaining a well-ventilated workspace, this article explores the key measures that one should take in order to protect themselves and others from potential hazards while welding.

Review contents

Safety Precautions for Welding

Welding is a critical process that requires careful attention to safety measures to ensure the well-being of the welder and the surrounding environment. At [company name], we prioritize safety above all else, and we want to share some important safety precautions for welding that can help prevent accidents and protect everyone involved.

This image is property of www.millerwelds.com.

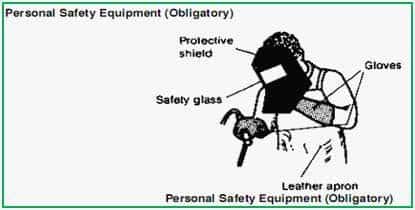

Proper Personal Protective Equipment (PPE)

When it comes to welding, wearing the appropriate Personal Protective Equipment (PPE) is essential. As responsible welders, we always make sure to have the right gear on hand before starting any project. This includes wearing a welding helmet with a proper lens shade to protect our eyes from harmful ultraviolet and infrared radiation. Additionally, we wear flame-resistant clothing, gloves, and boots to safeguard against sparks, molten metal, and potential electrical shocks.

Ensure Adequate Ventilation

Maintaining proper ventilation is crucial during welding operations. Welding produces hazardous fumes and gases that can be harmful to breathe in, so it is vital to work in a well-ventilated area or use local exhaust ventilation systems. By ensuring adequate ventilation, we minimize the risk of inhaling toxic substances, such as manganese, chromium, and nickel, which are present in welding fumes. Remember, fresh air circulation is key to maintaining a safe work environment.

Safe Handling and Storage of Welding Equipment

Proper handling and storage of welding equipment are paramount for safety. We diligently follow the manufacturer’s guidelines for handling and storing welding machines, gas cylinders, and other related equipment. It’s important to use the appropriate lifting techniques to avoid strain or injury when moving heavy machinery. Additionally, gas cylinders should be stored upright, secured, and away from any potential hazards, such as open flames and electrical circuits.

Prepare the Work Area

Before starting any welding project, we ensure the work area is well-prepared for safety. This involves clearing the area of any flammable materials, such as debris, oil, grease, or chemicals that could potentially ignite. Keeping the workspace clean and free from clutter not only reduces the risk of fire but also allows for better maneuverability during the welding process. Furthermore, we make sure the work area is adequately illuminated, enabling us to see clearly and avoid accidents.

This image is property of nasdonline.org.

Fire Prevention Measures

Fire prevention is a critical aspect of welding safety. As responsible welders, we take several precautions to prevent fires during the welding process. We always have a fire extinguisher nearby, ensuring it is easily accessible and properly maintained. It’s also crucial to keep welding sparks and slag away from combustible materials, as they can quickly ignite. By implementing fire prevention measures, we reduce the risk of accidents and ensure a safe working environment.

Electrical Safety

In welding, electricity is a significant hazard that requires careful attention. We prioritize electrical safety by inspecting the welding equipment for any damaged cords or loose connections before each use. Moreover, we ensure that the welding machine’s electrical supply is correctly grounded and that we adhere to all electrical safety protocols. By taking these precautions, we greatly minimize the risk of electrical shocks and potential fires caused by electrical malfunctions.

This image is property of www.cruxweld.com.

Avoid Exposure to Hazardous Substances

Welding involves working with various hazardous substances that, if not handled properly, can pose serious health risks. We protect ourselves from harmful exposure by utilizing local exhaust ventilation systems to remove welding fumes and gases from the breathing zone. Additionally, we wear respirators when necessary to filter out any remaining hazardous particles in the air. By avoiding direct contact with hazardous substances, we safeguard our health and well-being.

Prevent Welding Hazards with Safe Practices

Safe practices are the foundation of welding safety. We adhere to a set of comprehensive guidelines to prevent welding hazards and promote a secure working environment. Some of these practices include inspecting welding equipment regularly, properly grounding electrical systems, and avoiding welding in confined spaces unless specific safety measures are in place. By consistently following safe practices, we minimize the likelihood of accidents and ensure a culture of safety.

This image is property of aqcinspection.com.

Proper Training and Certification

Proper training and certification are vital for anyone engaged in welding activities. At [company name], we recognize the importance of continuous learning and skill development in order to maintain a high level of safety standards. Our team members undergo extensive training programs to ensure they have a thorough understanding of welding techniques, equipment operation, and safety protocols. By investing in proper training and certification, we equip ourselves with the knowledge and skills necessary to safely carry out welding operations.

Emergency Preparedness and First Aid

Accidents can happen unexpectedly, which is why being prepared for emergencies is crucial. At [company name], we have comprehensive emergency response plans in place, and our team members are trained on how to respond effectively in case of an accident or injury. Additionally, we ensure that first aid supplies are readily available and that our welders are trained in basic first aid techniques. By prioritizing emergency preparedness and first aid, we are able to provide immediate medical attention and minimize the severity of injuries.

In conclusion, welding safety is of utmost importance, and by implementing these safety precautions, we ensure a secure working environment for everyone involved. At [company name], we understand the significance of adopting safe practices, providing proper training, and prioritizing the well-being of our team members. By adhering to these precautions and consistently promoting a culture of safety, we can prevent accidents and create a positive and secure welding environment.

This image is property of cdn.shopify.com.